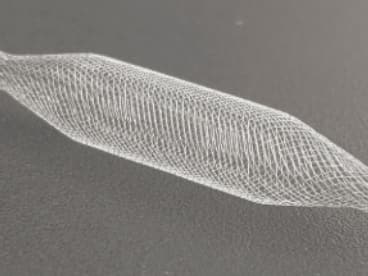

Braided Nitinol components are widely used in medical devices due to the flexibility, tailorable properties, and ability to form braids into complex shapes. Common applications for braided nitinol include:

- Neurovascular aneurysm devices

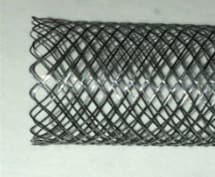

- Stents and flow diverters

- Thrombectomy clot retrievers

- Embolic protection

- Structural Heart

- Expandable catheter shafts

- Electrophysiology catheters

Confluent combines expertise in both braiding and nitinol technologies to provide our customers with braided components. Offering integrated production capabilities from melt to the finished components, Confluent is uniquely positioned to provide our customers industry leading lead times and supply chain stability.

Nitinol Materials

Due to its unique properties including superelasticity, shape memory and biocompatibility, demand for Nitinol in medical applications is quickly growing. Confluent’s industry leading SE508 and SE508 ELI nitinol alloys provides a stable supply chain for our components customers.

Braided components commonly use fine wire diameters down to 25μm (0.001”) . Given these small cross sections, Confluent’s unique ultra-low-inclusion SE508 ELI alloy is the device industry’s material of choice to achieve uniform properties and excellent strength and fatigue performance in these fine-wire braided components.

Capabilities:

Confluent was one of the first companies to introduce Nitinol to the medical device industry. With decades of experience producing implantable Nitinol components, if you need a capability, we likely have it.

- Looped atraumatic ends

- Polymer coverings

- Complex geometries

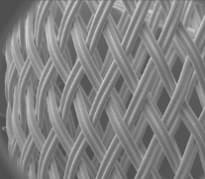

- Wire sizes down to 25μm diameter (0.001”)

- Braiding carrier (16, 48, 64, and 96)

- 1-over-2, 1-over-1, or 2-over-2 geometries.

- Welding

- Shape setting and Af testing

- Etching and Passivation

- Electropolishing

Confluent is proud to be the market leader in all things Nitinol. With a US-based vertically integrated supply chain and hundreds of years of combined industry knowledge, our team is able to supply material, expertise, and solutions to your next medical device project. Visit www.confluentmedical.com to learn more or email [email protected] for a custom quote today.