Solvent widely used in Polyimide production under review by EPA; rules and restrictions expected.

- Electrophysiology

- Cardiovascular

- Urological stone retrieval

Polyimide suppliers have historically used NMP (n-Methyl-2-pyrrolidone) as a solvent in the manufacturing process. In a recent finding that could have ramifications in the industry, the EPA has found that NMP, as a whole chemical substance, presents “an unreasonable risk of injury to human health when evaluated under its conditions of use.” This finding determined that NMP posed an unreasonable risk to health in 29 of 37 use cases, which include domestic manufacturing, import, processing in plastics manufacturing, various other industrial uses, as well as disposal. The EPA is expected to propose a set of risk management actions, which will then be followed by a public comment period. There is still substantial uncertainty as to the final restrictions, which puts the established filmcast polyimide supply chain in question.

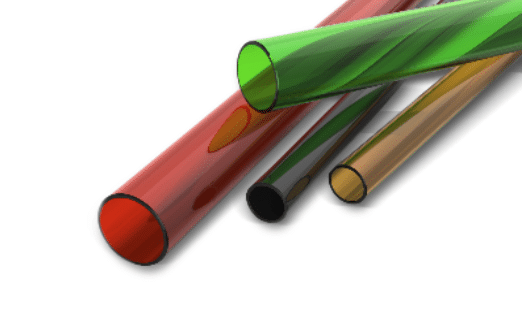

To mitigate this risk to the medical industry’s supply chain, Confluent has developed an NMP-Free option with equivalent performance to historical polyimide along with a stable supply chain. This material meets Europe’s REACH compliance requirements, avoids the impending EPA findings against NMP, and provides improved safety for our employees, vendors and patients.

We urge our customer’s supply chain professionals to do their own research and come to their own conclusions on NMP and their polyimide supply chains. Below is Confluent’s current understanding of the answers to some common questions.

Why has the EPA come to this finding?

- NMP was found to poses risks from both Acute and Chronic exposures through inhalation and the dermal contact, including developmental and reproductive toxicity. In addition to the reproductive hazards posed, additional risks included liver and kidney toxicity, immunotoxicity and neurotoxicity.

Have other chemicals recently been found to, as a whole chemical, pose unreasonable risk?

- Trichloroethylene (TCE) was found by the EPA to pose unreasonable risk in January 2023, and proposed risk management rules by October 2023 which would ban most uses of TCE within 1 year; including manufacturing, processing, and commercial and consumer product applications. A public comment period on the proposed rule is open until February 27th, 2024. From Confluent’s discussions with experts in the industry, it appears NMP may be on a similar trajectory.

What is the likely outcome of the NMP rulemaking / risk management actions?

- We simply don’t know. The outcome could range from more stringent PPE requirements (though the EPA’s stance is PPE use cannot be presupposed in evaluating risks) to targeted restrictions in specific applications, up to a ban on manufacture, import and use. The proposed regulations are anticipated to be released in 2024, followed by a public comment period.

What can Medical Device companies do to avoid supply disruption?

- Requalifying alternate materials vendors is often no small feat. It is recommended to get ahead of the curve requalifying an NMP-Free supply chain, proactively mitigating the risk before potentially being forced to do so quickly.

If you would like to discuss further and learn more about Confluent Medical’s NMP free alternative, our experts are ready at https://confluentmedical.com/. Our team will also be at the upcoming MD&M West show if you would like to discuss in person.