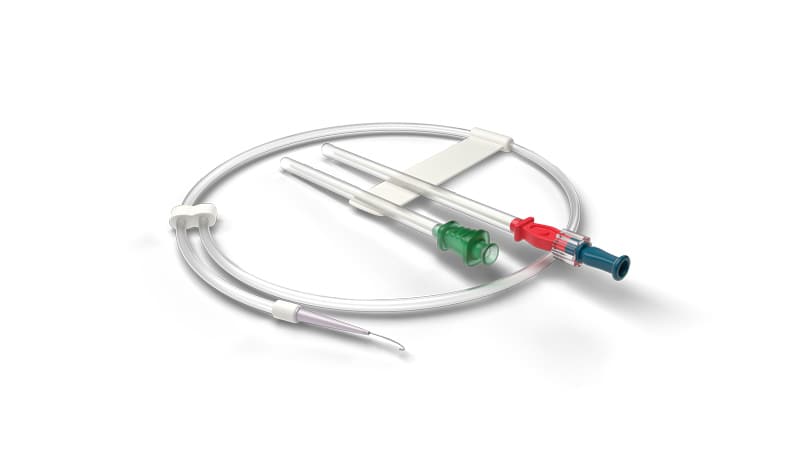

Confluent Medical Technologies specializes in the design, development, and manufacturing of highly precise complex catheter components and assemblies. Our extensive production capabilities enable us to perform secondary operations for all types of components involved in complex catheter systems

Materials

Stainless Steel, Non-metallic, Radiopaque

Stock Stainless Steel Braid Sizes

Flat: 0.0005″x0.003″ 0.0007″x0.003″

0.001″x0.003″ 0.001″x0.005″

Round: 0.001″ 0.002″

(Custom sizes available upon request)

Confluent Medical Technologies is committed to offering speed during development and scalability during production. We have dedicated prototyping resources and are committing to our lead times.

Contact Confluent Medical today and make sure your project is supported by our unmatched resources, technical expertise and proven service to meet any design, modification or manufacturing requirements.

Confluent Medical Technologies © 2025 All Rights Reserved.