Confluent Medical Technologies has added Calendar Textile Finishing capabilities at our Warwick, Rhode Island facility to advance what’s possible with woven and knit textiles. This tech expansion enables tailored fabric thickness and permeability properties of biomedical textiles, controlling profile and porosity of textiles used in transcatheter devices.

Calendering is a textile finishing operation, pressing a textile between a set of rollers at temperatures near the glass transition to reduce thickness and porosity. The added capability expands Confluent’s textile design toolbox for devices requiring materials with:

- Low profile

- Low Permeability (e. porosity)

- Low Tissue Ingrowth

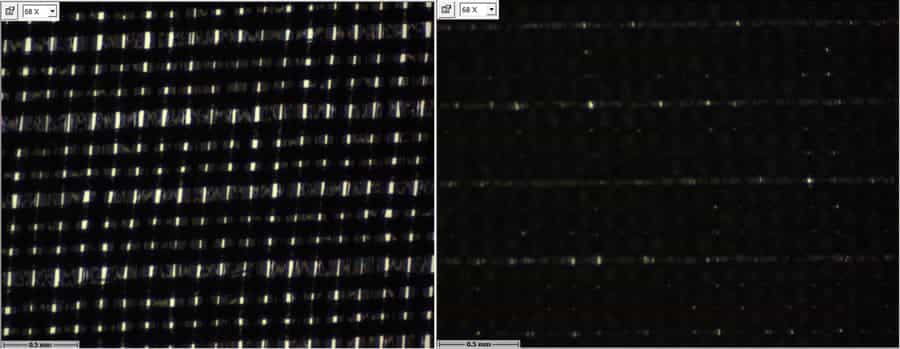

A demonstration of calendaring technology is shown in the images below, with a side-by side view of a woven fabric before & after calendaring. Prior to calendaring (left image), the textile has a large pore size that would offer a minimal blood barrier and facilitate cell infiltration over time. For comparison, the same woven material after calendaring (right image) is shown demonstrating greatly reduced porosity; further, the thickness has been reduced by over 50%.

(Left) Woven medical textile prior to calendaring, showing an open porous structure. (Right) The same woven textile after calendaring, with a low porosity structure and improved barrier properties.

Calendared fabrics have opportunities to improve performance in components such as the inner skirts of transcatheter heart valves, which are used to protect the delicate leaflets from the metal frame and require low profile and resistance to cell infiltration. Similarly, calendared fabrics advance capabilities for low permeability grafts and valve skirts where a blood barrier is required.

Consider the biomedical textiles experts at Confluent an extension of your own design team. Whether it’s a calendared fabric, or another solution from our woven, knit, non-woven and braid capabilities, our experienced team thrives on tailoring these products to meet your stringent development requirements.