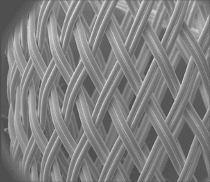

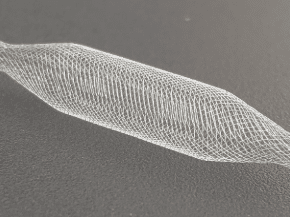

Braided components often prove advantageous due to their reduced radial strength and improved flexibility, with common applications including flow diverters and occluders. This added capability builds upon Confluent’s product offering along-side laser cut components and providing our customers with a full suite of solutions for their next gen devices.

- Flow diverters

- Neuro and peripheral vascular stents

- Aneurysm repair device