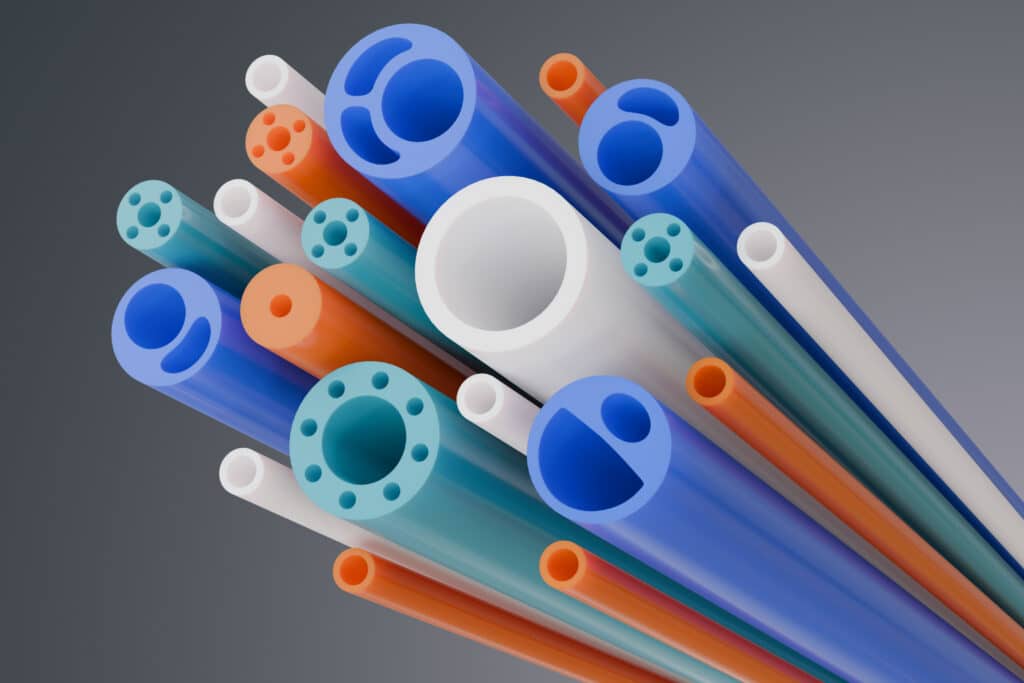

Extruded Tubing

Confluent Medical Technologies offers an array of medical extrusion services to the medical device industry. Our dedicated extrusion team specializes in custom medical extrusions and can help you develop complex configurations that meet unique restrictions and specifications.

Extrusion Capabilities

- Standard medical grade materials include: PEBAX, Nylon, Polyurethane, Polyester, and other thermoplastic elastomer materials

- Outer Diameters ranging from 0.010″ to 0.500″

- Wall thickness ranging from 0.005″ to 0.250″

- Discrete lengths or spools available

- Full range of design, prototyping, and development services

- In-line Gauging and Monitoring

- Ultrasonic wall thickness & measurement

- Multi-axis laser outer diameter measurement

- Statistical process control and data collection

- Advanced vision measurement system

Thermoplastics

- Nylon 6/6

- Polypropylene

- Custom Compounds

- Nylon 11 (ex. Rilsan)

- Nylon 12 (ex. Vestamid, Grilamid)

- PEBAX (All durometers)

- TPU (ex. Pellethane, Tecothane, Texin)

- PE (ex. OREVAC, MARLEX, DOWLEX, REPSOL)

- Polyesters (ex. Hytrel,PET)

- SEBS (ex. C-Flex, Krayton)

No high temperature thermoplastics (ex. PEEK, PVC, Delrin)

Multi-Lumen

Single Lumen

Minimum tube size: .010″ (OD)= Tolerance + .0005″

Multi- Lumen Extrusion

Minimum tube size .030″ (OD)= Tolerance + .001″

Try-Layer Tube

Minimum tube size: .018″ (ID) x.021″ (OD)= Tolerance + .0005″

Try-Layer Tube

Minimum tube size: .018″ (ID) x.021″ (OD)= Tolerance + .0005″

Facility Specs

- About 3,200 square feet of cleanroom manufacturing space in Laguna Niguel, CA

- ISO 13485 certified

- 100% medical tube dedicated with quick turnaround extrusion team

- 4 thermoplastic extrusion lines (1 dedicated R&D line)

- Temperature-controlled manufacturing room (60F to 85F)

- ISO 8 (Class 100,000) clean room for manufacturing, inspection, and packaging

Partnering with you every step of the way

Contact Confluent Medical today and make sure your project is supported by our unmatched resources, technical expertise and proven service to meet any design, modification or manufacturing requirements.