Biomedical Textiles

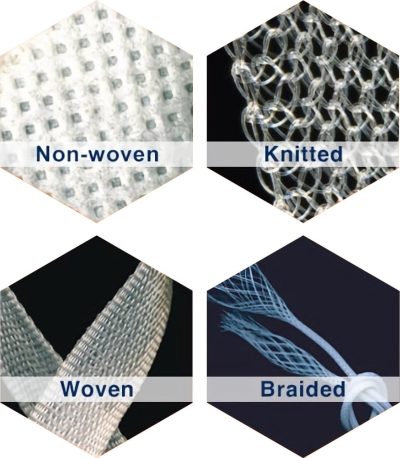

Confluent’s Biomedical Textiles service the Cardiovascular, Orthopedic, and Tissue Engineering markets. Woven, Knit, Braided, and Non-Woven implantable medical textiles are building blocks for medical devices. Trust our proven textiles expertise to assist you from initial concept development through large-scale production.

Biomedical Textiles Capabilities

Confluent specializes in 4 core textiles technologies:

- Wovens (flat fabrics and 3D structures)

- Knits (flat or tubular constructs)

- Braids (from 3 to 96 ends, round, flat, and bifurcating structures)

- Non-Wovens (Sheets, plugs, and tubular forms of resorbable materials

Our textiles may be provided in bulk packaging, or cut and packaged as finished components. Confluent’s Laser Cut Textiles provide the tightest tolerances for vascular textiles. All components manufacturing in ISO7 and ISO8 clean rooms in an ISO 13485 facility.

Markets & Applications

Our team has experience with the development and manufacturing of implantable textiles for head-to-toe applications. Common medical segments Confluent supports with textile components include:

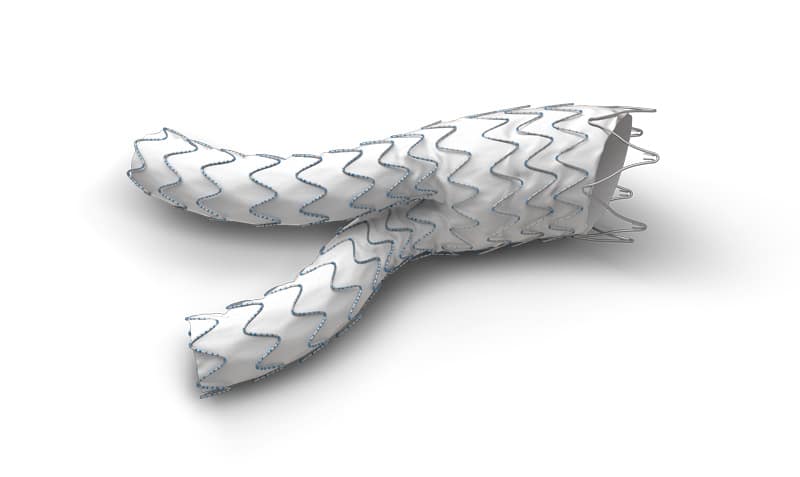

- Cardiovascular: Aortic and Mitral transcatheter valve skirts, Atrial appendage occlusion device coverts, or endovascular stent grafts

- Orthopedic: Sports Med Sutures and assemblies, joint and ligament fixation and reconstruction devices, spinal fixation tethers

- Tissue engineering with cell scaffolds, and resorbable wound healing materials

Electrospinning

Confluent has partnered with The Electrospinning Company to provide sutureless attachments of textiles to a device frame. Eliminating the need for sewing and manual assemblies which reduces cycle times and costs.

Opportunities & Benefits

- Occluders, heart valves, and stent grafts

- Eliminate sewing and Manual assemblies

- Reduce cycle times & cost

- Bespoke textile properties

- Ability to mimic extracellular matrix

- Localized/gradient properties

- Tailored structure & functionality

- Wide range of materials

- Suitable for self-expanding and balloon-expanding stents

Rapid Iteration

Confluent’s dedicated textiles rapid prototyping center provides you with the perfect partner for the fast moving concept development.

- Best in Class Lead times

- Expert Textiles Engineering Support

- Industry leading capabilities

With capabilities mirroring our high volume manufacturing facility. Confluent’s textiles prototyping center allows for quick iteration and downselection of concepts with a smooth transition to production.

Partnering with you every step of the way

Contact Confluent Medical today and make sure your project is supported by our unmatched resources, technical expertise and proven service to meet any design, modification or manufacturing requirements.